This is where copper could come to the rescue if it were more widely used. The Ancient Egyptians, Greeks, Romans and Aztecs used copper-based preparations to treat burns, sore throats and skin rashes, as well as for day-to-day hygiene. Greek soldiers are reported to have scraped the bronze from their swords into open wounds to reduce the likelihood of infection during battles.

In a similar vein, the French physician Victor Burq extensively studied various cholera outbreaks in Paris during the 1850’s. He soon noticed that copper workers – who otherwise lived in very poor hygienic conditions – were hardly affected. In fact, Burq could not find any deaths of jewellers, goldsmiths, or boilermakers—all those who worked with copper. Within the ranks of the army, he found that musicians who played brass instruments (brass is partly copper) were also protected.

Copper is anti-microbial

Today, we know precisely what protects a person handling copper day in and day out from a bacterial threat: Copper is antimicrobial. It kills bacteria and viruses, sometimes within minutes. Among the list of microbes copper defeats quite easily are norovirus, MRSA, a staph bacteria that has become resistant to antibiotics, virulent strains of E. coli that cause food-borne illness, and coronaviruses – possibly including the novel strain currently causing the COVID-19 pandemic.

This has important implications for the use of this material: If copper were more frequently used in hospitals, in high-traffic areas, where many people touch surfaces teeming with microbial life or even in drinking water piping systems, it could play an invaluable role in public health. However, many institutions opt for plastic or stainless steel, depending on the application. Many of the microbes that make us sick can live on hard surfaces for up to four or five days. When we touch those surfaces, the microbes can make it into our bodies through our nose, mouth, or eyes, and infect us.

On copper surfaces, bacteria and viruses die. When a microbe lands on a copper surface, the copper releases ions, which are electrically charged particles. Those copper ions blast through the outer membranes and destroy the whole cell, including the DNA or RNA inside, so that a bacteria or virus cannot mutate and become resistant to the copper, or pass on genes (like for antibiotic resistance) to other microbes. What is more: A study from 2015 found that a different coronavirus (229E), could still infect a human lung cell after five days of being on materials like teflon, ceramic, glass, silicone rubber, and stainless steel. But on copper alloys, the coronavirus was rapidly inactivated.

Does copper help against Corona?

In a new preprint on SARS-CoV2, the strain that causes COVID-19, researchers at the National Institutes of Health virology laboratory in Montana sprayed the virus onto seven different common materials, reported MIT Technology Review. They found that it survived the longest—up to three days—on plastic and stainless steel, suggesting that surfaces in hospitals or steel poles on public transit could be places where people pick up the illness. Just a single droplet from a cough or sneeze can carry an infectious dose of a virus.

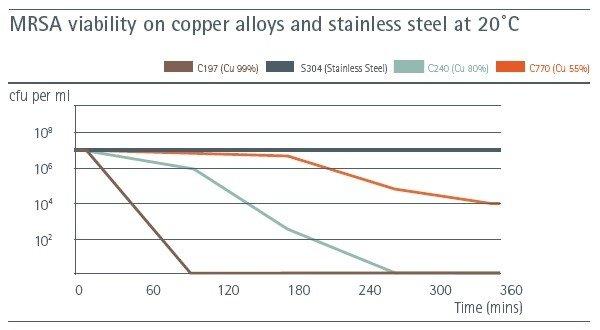

Laboratory tests conducted by the European Copper Alliance have come to similar conclusions. The graph below shows that surfaces with a certain copper content kill bacteria and viruses in sometimes as little as 90 minutes (for more information visit https://copperalliance.org.uk/knowledge-base/education/education-resources/copper-pathogens-disease/).

Could copper have helped prevent the current situation?

Nobody knows this for certain. However, its properties are unmistakable, and judging by the effects COVID 19 has on not only human health but also on the economy, any ostensibly higher up-front cost pales to nothing.

Drinking water is another hygienically critical area. While water as such does not transmit coronaviruses and much of the piping is hardly ever touched, having unlimited, completely maintenance-free piping and fittings with anti-microbial properties that is simultaneously ideally suited for contact with water sounds like an excellent idea to many. SANHA provides various piping systems made from copper or copper alloys, many of which such as the press fit series 6000 have extensive certifications like WRAS, CSBT, or TÜV.

copperalliance.com

The SANHA group is one of the leading European manufacturers of press fit pipe systems for drinking water, gas, solar, heating, cooling and sanitary applications for use in domestic and industrial settings. We have approximately 8500 items in our product ranges, covering most commonly used materials such as copper, copper alloys, stainless and carbon steel, as well as our innovative silicon bronze, lead-free fittings for use in drinking water applications.

SANHA GmbH & Co. KG

Im Teelbruch 80

45219 Essen

Telefon: +49 (2054) 925-0

Telefax: +49 (2054) 925-250

http://www.sanha.com

Teamleiter Marketing & PR

Telefon: +492054925160

E-Mail: sven.kalbitzer@sanha.com

![]()