- Virtual demo of solutions for bars, bakery products and crackers

- Elimination of trim during bar slab forming thanks to WRW Flex compression roller

- Cold-sealing paper application on Sigpack HRM flow wrapper

- Heat-sealing paper application on Pack 403 flow wrapper

- Amplified heat sealing technology for monomaterials on Sigpack HCS flow wrapper

Since interpack 2020 was postponed, Syntegon Technology is exhibiting a number of horizontal seamless systems online at their virtual show. The experts for intelligent and sustainable technologies are introducing three complete solutions for bars, cookies or crackers, and bakery products. The systems all have one thing in common: They offer customers flexible equipment from a single source with a number of sustainability benefits.

In primary packaging, the innovations from Syntegon Technology facilitate flow wrapping with mono-materials and paper. The new Kliklok ACE carton former premieres glue-free carton and tray forming, while the TTM top load cartoner and Elematic 2001 case packer reliably process recycled and grass fiber cardboard, respectively. “With years of research experience at our innovative test labs and engineering centers, customers benefit from our comprehensive expertise and broad portfolio of customized and sustainable solutions – from small start-ups to multinational manufacturers,” Bruno Oberle, general manager and vice president horizontal packaging systems at Syntegon Technology, says.

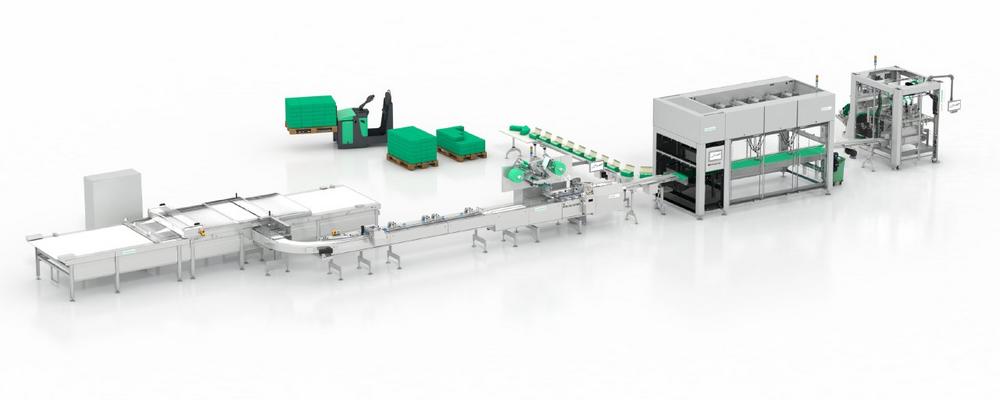

Seamless paper packaging system for bars

At their virtual show, Syntegon Technology is showcasing a high-speed seamless system for bars, including all steps from process technology up to case packing. With the new WRW Flex compression roller, manufacturers can adjust the height and width of their bar mass slabs during production with maximum flexibility and precision. This minimizes trim, thus eliminating product waste. Once the bars are cut and fanned out, they are fed into the Sigpack HRM flow wrapper by the contactless, format-flexible and compact Sigpack FIT infeed with XTS linear motor technology. The HRM features the new paper-ON-form retrofit kit in combination with cold sealing technology – the first of its kind to process paper packaging without compromising on speed and product safety.

The seamless system comes with the proven Sigpack TTM top load cartoner. The gentle feeding module Sigpack FWV makes sure that the paper flow wrap’s sensitive barrier layer remains intact, even at maximum speeds. This is a major quality benefit throughout the overall packaging process. What is more, the Sigpack TTM processes cardboard made from 95 percent recycled fibers with utmost precision. In the final step, the Elematic 2001 packs the cartons into cases. The case packer stands out for its efficient use of packaging materials, including slightly bent blanks as well as grass fiber corrugated board. The machine can handle up to 100 different case designs with a speed of up to 40 cases per minute.

Versatile packaging system for bakery applications

For bakery products, such as cupcakes, Syntegon Technology is presenting an all-round packaging system, featuring the direct depositing pullnose distribution station, the new Pack Feeder 4 and the Pack 403 horizontal flow wrapper. The Pack 403 flow wrapper is also equipped with the paper-ON-form retrofit kit to flow wrap cupcakes in paper. Unlike the bar system, the Pack 403 uses heat sealing combined with the paper forming unit. This provides tight seals, even with highly insulating paper materials. Once flow wrapped, the Paloma robotic pick and place solution arranges the cupcakes for the downstream tray-forming equipment. The bakery system is completed by the new Kliklok ACE carton former. The platform forms cartons and trays without the use of glue. The Kliklok ACE is celebrating its global debut at Syntegon Technology’s virtual show on May 7, 2020.

Compact and high-speed packaging system for cookies and crackers

In addition, Syntegon Technology is presenting a compact and high-speed solution for cookies and crackers, producing tight packs with fully recycable mono-material films. The Sigpack HCS flow wrapper is equipped with the latest amplified heat sealing (AHS) technology. Thanks to extended sealing times, the flow wrapper can process a large variety of films at very high speeds. Materials range from multi-layer films to fully recycable mono-materials. The precise application of heat to the film guarantees tight packs. In terms of product handling, the system includes the new Sigpack FGMT (FGM-Turbo) measuring solution. It continously portions products into the defined slug length. Format adjustments can be made on the HMI at the push of a button. It is based on linear motor technology, which offers particularly gentle handling for cookies and crackers – even at very high speeds. To round it off: The Kliklok MEC endload cartoner is seamlessly integrated into the system. The cartoner is highly flexible in terms of carton styles and sizes. It offers tool-less changeovers, a stainless steel execution and optimal operator access. The Kliklok MEC also processes cardboard with a high proportion of recycled material.

To find out more about Syntegon Technology’s seamless systems and sustainable innovations, please visit the virtual show from May 7 to 13, 2020. Full details to follow.

Syntegon Technology is a leading global process and packaging technology provider. Formerly the packaging division of the Bosch Group, the company, headquartered in Waiblingen (Germany), has been offering complete solutions for the pharmaceutical and food industries for over 50 years. More than 6,100 employees at 30 locations in more than 15 countries generated a total revenue of 1.3 billion euros in 2019. The portfolio of intelligent and sustainable technologies includes stand-alone machines, as well as complete systems and services. Fields of application in the pharmaceutical industry are the production, processing, filling, inspection and packaging of liquid and solid pharmaceuticals (e.g. syringes and capsules). In the food industry, the portfolio includes process technology for confectionery as well as packaging solutions for dry foods (e.g. bars, bakery products and coffee), frozen foods and dairy products.

Syntegon Technology GmbH

Stuttgarter Str. 130

71332 Waiblingen

Telefon: +49 (7151) 14-0

http://www.syntegon.com

Telefon: +49 (7951) 402-648

![]()