- KOV-111-16 developed specially for building materials industry

- Product protection thanks to new edge protection setter

- Fully automatic balk feeder for non-palletised goods

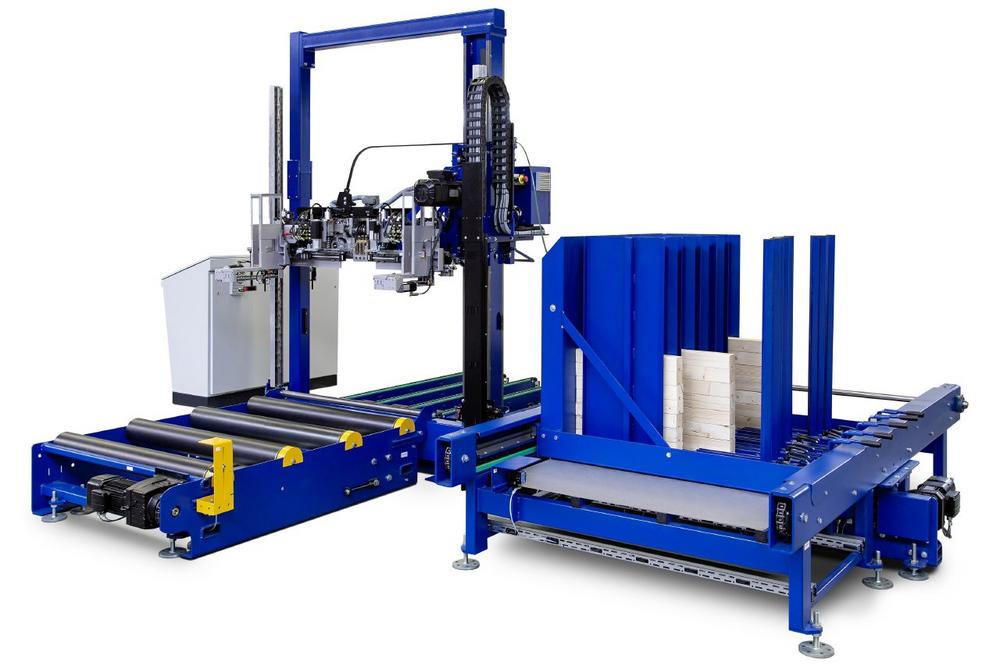

The KOV-111-16 system of Mosca GmbH secures large-volume timber products for transport without significant downtime. Three new features ensure even greater reliability and safety. The high-performance sealing unit with a tensile force of up to 7,000 Newton enables heavy products to be strapped safely with 19-millimetre plastic strap. The new balk feeder and the fully automatic edge protection setter optimise product protection.

If the production of timber, chipboard, or other building materials is to run smoothly, the process of securing goods for transport must be able to keep pace with upstream production systems. Thanks to its new features, the KOV-111-16 straps goods with special product protection and almost no downtime. Integrated into conveying systems made by Mosca or other manufacturers, the fully automated machine feeds balks under the product to be strapped and protects the upper edges with solid cardboard. Any downtimes for refilling consumables such as strapping, balks, and edge protection have been reduced to a minimum thanks to large magazines for balks and edge protection setters. Timo Mosca, CEO of Mosca GmbH, explains: “In combination with the high-performance sealing unit developed by us, we offer a solution that is specially tailored to the needs of the timber industry”.

The new high-performance sealing unit achieves strap tension of up to 7,000 newtons. This allows the use of 19-millimetre strapping material with a thickness up to 1.3 millimetres. These straps provide a tensile strength of up to 10,000 newtons – ideal for strapping heavy products.

More functionality with balk feeder and edge protection setter

The KOV-111-16 magazine holds 75 balks of up to five different lengths. During operation, the magazine moves horizontally below the non-palletised product to feed balks of the right length. When the carriage is not moving, the magazine can be reloaded manually, avoiding costly downtimes.

The fully automated edge protection setter also helps to keep downtimes to a minimum thanks to a large magazine that holds up to 130 pieces. Like the sealing unit, the magazine is located in the top platen of the KOV-111-16. As soon as the conveying system moves the products to the machine, the top platen moves downward for strapping. It automatically detects the edges of the product and sets the edge protection precisely. This allows more flexibility for different product heights and widths. Customers who want to further reduce downtimes can order the optional new-generation BSG-4 strap sealing unit. It seals the strap end of the depleted coil to the strap end of the new coil, reducing coil-replacement time to a minimum. The newest version is equipped with a battery, allowing a single device to switch back and forth among several machines.

Efficiency, flexibility and an option to secure the strap

The complete system is powered by electricity and does not require costly pneumatics. All drives are intelligently controllable, so that the product can be reached in every position by both the edge protection setter and the balk feeder. This gives customers maximum flexibility.

An optional slot cutter prevents strap damage or slipping. The strap is securely placed in the groove and does not come into contact with the floor.

Mosca GmbH is a system supplier, developer and producer of high-quality strapping machines, strapping materials and safety systems for transporting goods for professional and industrial use. The machine portfolio ranges from universal devices with a wide range of applications, to fully automated high-performance machines that can be integrated into any higher-level automation line. Mosca produces strapping material out of PP and PET in one of the most modern sites in Europe. Mosca’s international distribution, service and consulting network enables global service for customers. Based in Waldbrunn (Germany), the family company was founded in 1966 and is present in 16 countries with 18 offices and six production sites in Germany, Malaysia, Canada and USA. It employs over 1000 employees. With continuous new developments, the strapping experts have maintained quality and technology leadership in the strapping sector for more than 50 years. Further information can be found at www.mosca.com

Mosca GmbH

Gerd-Mosca-Strasse 1

69429 Waldbrunn

Telefon: +49 (6274) 932-0

Telefax: +49 (6274) 932400-118

http://de-de.mosca.com/

PR-Seniorberaterin

Telefon: +49 (6221) 1877912

Fax: +49 (6221) 90574-11

E-Mail: mosca@commhaconsulting.com

Werbefachfrau für Online Marketing

Telefon: +49 (6274) 932-317

Fax: +49 (6274) 932400-317

E-Mail: nicole.frey@mosca.com

![]()