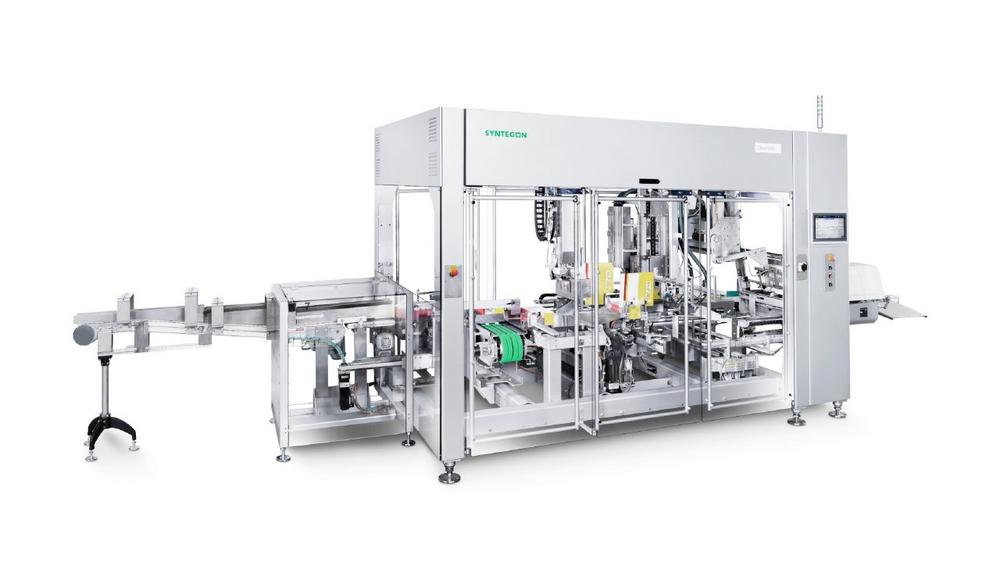

- Premier for SVE 3220 Doy Zip vertical bagger in combination with Elematic 2001 WAH case packer for powder applications and stand-up bags

- SVE 3220 Doy Zip for mono-materials allows a variety of bag styles

- Elematic 2001 WAH case packer for up to 100 case designs

Since interpack 2020 has been postponed, Syntegon Technology will present a bagging and case packing system for powder applications with brand new features online at their virtual show. The system yields a number of new sustainability benefits: the SVE 3220 Doy Zip vertical form, fill and seal machine can now use recyclable plastic and paper mono-materials. As a first, the Elematic 2001 WAH case packer can use corrugated blanks made from grass fiber. “We pay close attention to sustainability and pursue a ‘circular economy’ approach that is mirrored in the machines we are showing at our virtual show. Syntegon Technology strives to provide intelligent packaging solutions throughout the entire machine cycle,” Pierre Hamelink, director of global business, market and sustainability strategy for food (vertical) at Syntegon Technology in Weert, the Netherlands, explains.

Combination of SVE 3220 Doy Zip and Elematic 2001 for powder applications

Syntegon Technology offers a broad portfolio of packaging solutions for applications of any kind. At its virtual show, the company is exhibiting a comprehensive bagging and case packing system that suits the needs of powder foods producers, such as bakery and cake mixes, milk powder, infant nutrition, coffee or flour manufacturers, in particular. The SVE 3220 Doy Zip and the Elematic 2001 stand out for their high levels of flexibility and productivity. With a bag-filling degree of up to 80 percent on the SVE 3220 DZ, powder manufacturers now require less film to pack the same weight of product, thereby reducing packaging material consumption and contributing to sustainability. As part of the system, the Elematic 2001 packs 16 cases per minute, with each case containing five powder-filled stand-up bags. Since the two machines can both process recyclable materials, Syntegon offers a solution that supports manufacturers in their sustainability efforts.

Recyclable mono-materials for all vertical pack styles

The SVE 3220 Doy Zip vertical form, fill and seal machine has received a major upgrade in terms of sustainability. Manufacturers can now process sustainable polyolefin-based mono-materials as well as paper packaging, enabling them to pack their products in the most popular bag styles, namely pillow, gusseted, block bottom, corner seal and Doy (Zip) bags. The polyolefin-based mono-material can be recycled by pyrolysis and re-used in the food industry, while paper-based materials can be recycled via the waste-paper stream. Depending on the product and film specifics, existing Doy Zip machines from Syntegon can be retrofitted with upgrade kits for mono-material films.

The overall performance and flexibility of the SVE 3220 Doy Zip has been improved: bag heights of up to 320mm are now possible and format changes only take 30 minutes. The machine achieves an output rate of up to 100 Doy Zip bags per minute.

Flexibility and sustainability go hand in hand

The Elematic 2001 WAH case packer stands out for its efficient use of packaging materials, including the ability to work with bent blanks in particular. The machine has been developed with a view to offering maximum pack style flexibility: it can now handle up to 100 different case designs, from simple trays to complex shelf-ready tray and hood cases on one machine with a speed of up to 40 cases per minute. “Be it trays, trays with a hood, full wrap-around cases or ledge trays – the Elematic 2001 WAH offers our customers a solution that not only covers a wide variety of pack styles but also enhances the sustainability of their products. The Elematic click system enables quick, easy and reliable format changeovers for perfect results from the first case onwards,” Bernhard Vaihinger, product manager at Syntegon Technology in Remshalden, Germany, reports.

True to their mission to offer sustainable solutions for everyone, Syntegon Technology can now run corrugated board made from grass fiber on the Elematic 2001 WAH case packer. The machine can handle solid board and corrugated board of any quality as well as a combination of different packaging materials for trays and hoods. What is more, Syntegon Technology partners with packaging material suppliers of all kinds to test the machine runability of sustainable materials without compromising on speed and quality.

To find out more about Syntegon Technology’s sustainable packaging system for powder applications, please visit the virtual show from May 7 to 13, 2020.

Syntegon Technology is a leading global process and packaging technology provider. Formerly the packaging division of the Bosch Group, the company, headquartered in Waiblingen (Germany), has been offering complete solutions for the pharmaceutical and food industries for over 50 years. More than 6,100 employees at 30 locations in more than 15 countries generated a total revenue of 1.3 billion euros in 2019. The portfolio of intelligent and sustainable technologies includes stand-alone machines, as well as complete systems and services. Fields of application in the pharmaceutical industry are the production, processing, filling, inspection and packaging of liquid and solid pharmaceuticals (e.g. syringes and capsules). In the food industry, the portfolio includes process technology for confectionery as well as packaging solutions for dry foods (e.g. bars, bakery products and coffee), frozen foods and dairy products.

Syntegon Technology GmbH

Stuttgarter Str. 130

71332 Waiblingen

Telefon: +49 (7151) 14-0

http://www.syntegon.com

ABI Europe

Telefon: +49 (69) 710456239

E-Mail: acowan@abipr.com

Telefon: +49 (7951) 402-648

![]()