Choose the right material

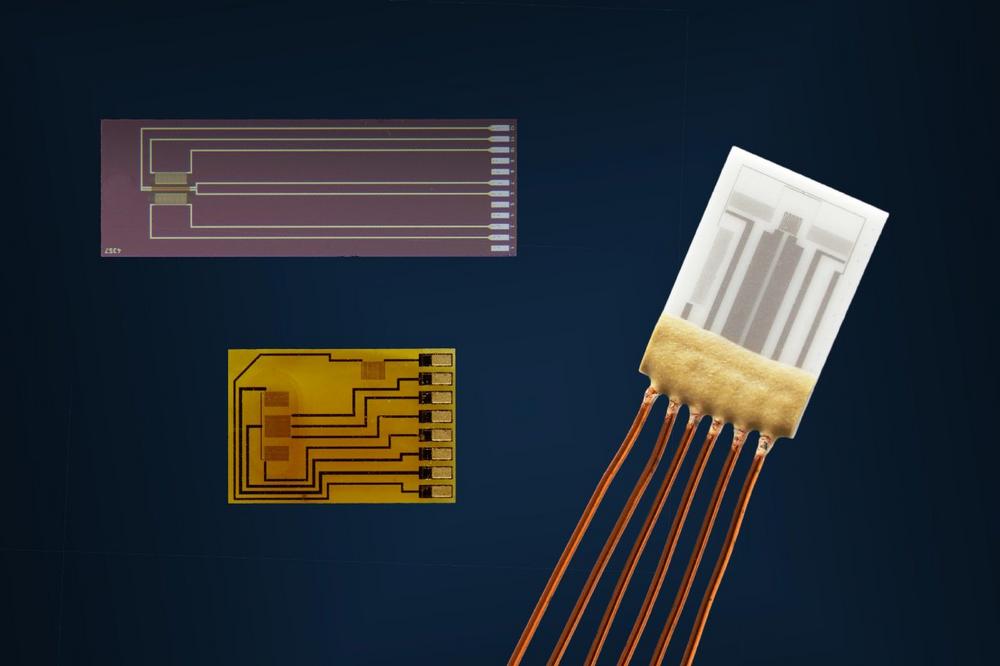

An inline flow sensor can be applied to monitor the flow through a cannula or mask and can be used to control the oxygen feedback loop. A simple and low-cost implementation was in mind during the development of the FS2 thermal mass flow sensor. While the SFS is made of silicon substrates, the FS2 is made of ceramic and glass which are inert, even if used in direct contact with 100% oxygen.

Other sensors and materials, FS7 and MFS02

During the development of the FS7, a simple implementation in combination with a robust and versatile material was achieved. The FS7 is also made of ceramic and glass (just like the FS2), however comes with only two resistors, which again allows an even simpler CTA (constant temperature anemometer) configuration when performing a flow measurement. For specialized applications, our MFS02 is made from polyimide and glass sensor construction materials.

Most modern ventilators can deliver flow rates between 60 and 120 L/min (which is 7 m/s with a 19 mm ID tube at peak flow). All sensor chips, the SFS, FS2, FS7 and the MFS02, cover a wide dynamic range and flow rates beyond the required flow volumes for a respirator application.

Innovative Sensor Technology IST AG is one of the global leaders in micro system technology, services and solutions for industrial measurement applications. The company employs approx. 400 personnel across the globe.

IST AG is a manufacturer and partner for physical, chemical and biological sensors. Its product range contains thin-film platinum and nickel RTD temperature sensors, capacitive humidity sensors, thermal mass flow sensors, conductivity and biosensors. IST AG also manufactures a broad portfolio of calibrated humidity modules. Additionally, a highly qualified technical team offers consulting, development and production of challenging customer requests in the field of micro system technology.

The wide product range is the choice of many renowned end customers and OEMs in their fields. As a result, IST AG sensors are found in measuring instruments for various applications, such as HVAC, automation, appliance, medical, test and measurement, aerospace, bio measurement and process control and many more.

Founded in 1991, Innovative Sensor Technology is headquartered in Ebnat-Kappel, Switzerland in the mountain region of Toggenburg. In 2005, Innovative Sensor Technology became part of the Endress+Hauser Group, headquartered in Reinach, Switzerland. The Endress+Hauser Group is among the global leaders in measuring instruments, services and solutions for industrial process engineering.

For further information, please visit www.ist-ag.com

Innovative Sensor Technology IST AG

Stegrütistrasse 14

CH9642 Ebnat-Kappel

Telefon: +41 (71) 99201-00

http://www.ist-ag.com

Marketing

Telefon: +49 (719) 920100

E-Mail: caroline.kooijmans@ist-ag.com

![]()