• Big order in the solar segment

• Use of innovative “Fusion” technology

• Reduced use of chemicals

• New expansion level for a production capacity of over 15 GW

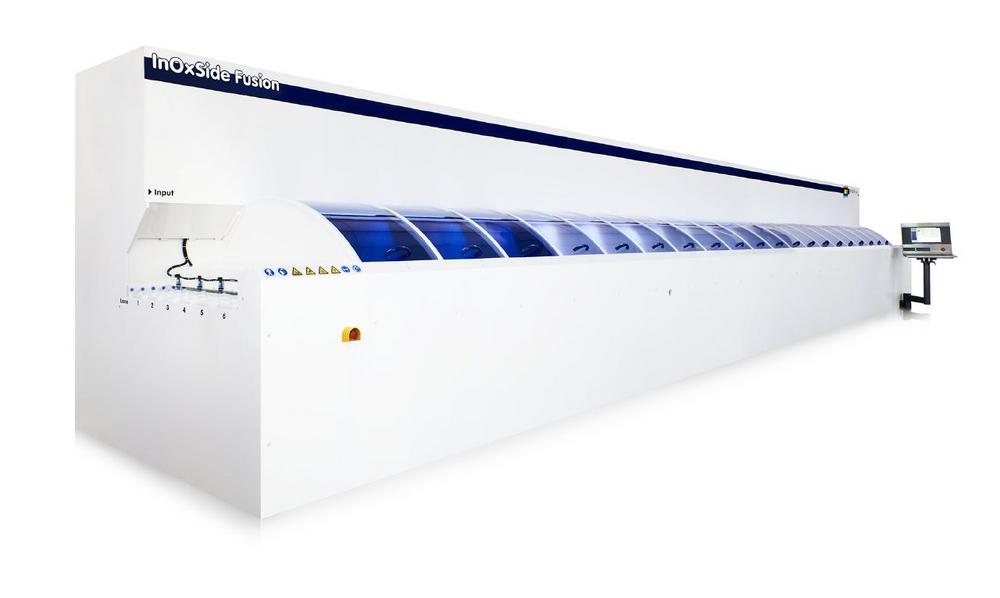

• BatchTex XL and InOxSide Fusion machines

• M12 wafer trend confirmed

In August this year, following an intensive initial phase, a Tier 1 Asian customer placed a big order worth tens of millions of euros. The result of innovative technology, the machines ordered, RENA InOxSide Fusion and RENA BatchTex XL, have a production capacity of over 15 GW and will be used in several plants for the next expansion level of PERC solar cell production. CEO Peter Schneidewind, explains: “We are very proud to say that this order is the biggest that RENA has ever received. We are implementing extremely innovative technology which has been developed by our teams in Germany and China in record time. We are delighted that the innovative strength of RENA and the reliability of our systems are valued by our customer.”

The newly developed InOxSide Fusion technology introduces a very short acid process with an additional alkaline process step. This development makes it possible to use significantly less nitric acid, leading to a reduction in production costs. The BatchTex XL machines ordered by the customer, for solar wafers, also help to optimize the cost framework.

“The comparatively space-saving solution offers our customer enormous potential savings and sets new standards in wet chemical processing technology. The trend towards M12 wafers continues to grow and thanks to our machines, we are extremely well prepared for it,” emphasizes Ulrich Jäger, Vice President Sales.

Peter Schneidewind continues: “Furthermore, several other solar cell manufacturers also expressed significant interest in RENA’s new technologies at SNEC, the leading exhibition for the solar industry. In the face of the continuing solar boom, our high-end solutions ensure we are effectively meeting the requirements of solar cell manufacturers when it comes to increasing their competitive ability.”

"THE WET PROCESSING COMPANY" RENA Technologies is a global leader in manufacturing production machinery for wet chemical surface treatment. RENA products are used in groundbreaking areas of application such as semiconductors, med-tech, renewable energies, the glass industry, and additive manufacturing. With RENA systems, surfaces such as semiconductor wafers, solar cells, optical substrates, dental implants, 3D-printed metal parts, and other high-tech products are treated or modified using wet chemical processes. RENA offers tried-and-tested standard machines as well as customized solutions, process support, and chemical performance additives.

RENA Technologies GmbH

Höhenweg 1

78148 Gütenbach

Telefon: +49 7723 9313 0

Telefax: +49 7723 9313 50

http://www.rena.com

Marketing Manager Multimedia

Telefon: +49 (7723) 9313-914

E-Mail: Dirk.Hensel@rena.com

![]()