Whether it is information for individual steps in production and logistics, for checkout operators or for end customers, labelling turns packaging into a communications and data medium. Behind the labelling are ultramodern systems that have to meet higher and higher performance standards, managing and applying all kinds of data. The solutions used include label dispensers and print dispensers, in addition to inkjet and laser printers.

Much of this important information is applied to the tape at high speed, as a peripheral process in the packaging line, which means workflows must be certain and reliable in order to avoid any interruptions to production. Recalls caused by erroneous information, labels that have not been cleanly attached or illegible codes must be reliably ruled out. After printing, label legibility is often reviewed using scanners for this reason, in order to sideline defective products immediately.

No labelling without a higher-level data connection

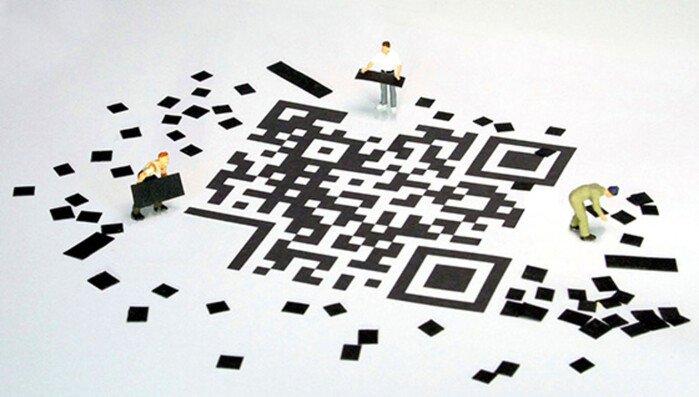

The data and information to be printed is stored and managed using software interfaces. Information required by law, such as batch numbers, information on the manufacturer, content and hazard information, must share the limited available space with marketing content and codes for logistics. At the same time, digitalization ensures that even small codes are able to store a large volume of information. As an interface between the product and the world of IT, labelling thus makes it possible to meet growing demands for process networking and the integration of packaging in all kinds of workflows. The information is applied as clear text, bar codes, and increasingly also in the form of QR codes, which offer new opportunities for communication with consumers and also serve as an important marketing tool. In turn, batch numbers ensure that products posing a potential risk for consumers can be swiftly recalled.

Given the stringent demands on labelling, these targets are not all that easy to implement – after all, they must ensure a high level of process safety and uncomplicated handling. In the case of foodstuffs, therefore, labelling at the manufacturer’s end takes place under difficult conditions: cold and moist surfaces, sometimes already deep-frozen, sometimes filled with hot product and then cooled, which means surfaces may be greasy, damp or uneven depending on the product. To overcome these challenges, suppliers have developed pressure-sensitive adhesives that provide minimum migration, i.e. the labels immediately stick to the various surfaces, facilitating fast labelling speeds in the packaging lines. At the same time, the adhesives must be safe for use with foodstuffs, and in the case of sealing labels they must be easy to open and be resealable.

Labelling as part of a sustainability strategy

Labels and printing inks must not be overlooked in terms of the recycling process. Ultimately, they must not cause problems in recycling facilities by being hard to remove or preventing the scanners from recognizing the actual packaging material. Ideally, therefore, they should be made of the same material as the product packaging, which is particularly important when the labels are shrunk around the packaging in the form of sleeves. With innovations such as labels made of stone paper, grass paper, compostable film and fully recyclable labels, the exhibitors at last year’s FACHPACK demonstrated a range of methods for integrating labels into a sustainable packaging strategy.

There are now also invisible Digimarc codes that are intended only for specific machines. This solution was developed for supermarket company Netto-Marken-Discount, and won the gold German Packaging Award in 2020. Unlike conventional bar codes, these codes are integrated into the packaging design, meaning products can be scanned from all sides. As a result, processes are much faster and easier along the entire value chain from packaging production, logistics and warehousing to the point-of-sale and purchasing process and finally recycling of the packaging. For example, the code can contain precise information about the packaging material used, which makes the detection and sorting process at the recycling facility more efficient.

In this way, the labelling systems of the future will contribute significantly to packaging sustainability and the result, thanks to their versatility, will be genuinely smart packaging.

NürnbergMesse GmbH

Messezentrum

90471 Nürnberg

Telefon: +49 (911) 8606-0

Telefax: +49 (911) 8606-8228

http://www.nuernbergmesse.de

Telefon: +49 (911) 860683-55

Fax: +49 (911) 86061283-55

E-Mail: christina.freund@nuernbergmesse.de

![]()