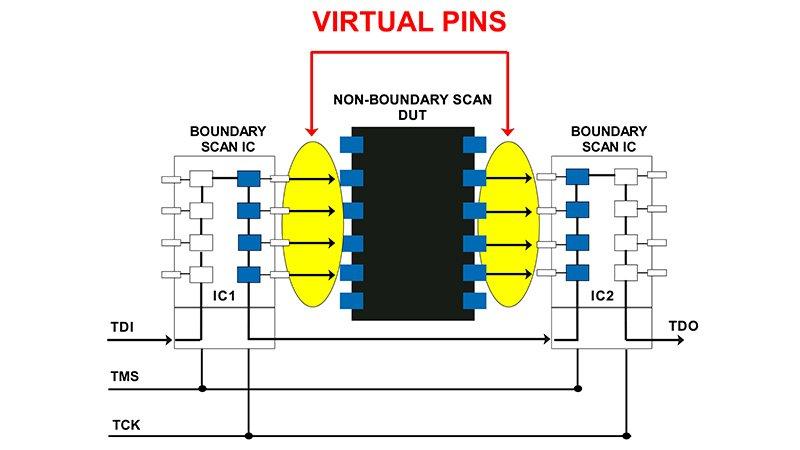

In order to be able to increase the own test coverage, the same standardised diagnostic protocol as an in-circuit test was used – in addition to checking the boundary-scan-capable component. In this case, the functionality of the non-boundary scan component is stimulated with the same function with which data is sent to and received from the boundary scan cell by controlling the corresponding input and recording its output signals. In principle, this is as if Digitaltest had built its own test drivers and sensors into the integrated circuits (ICs).

Digitaltest used the current capabilities of its own test system and controlled the Boundary Scan components via simple commands directly from the user interface. The tests could be performed by placing a "Virtual Pin" between a Boundary Scan component and a non-Boundary Scan component directly surrounding it.

Digitaltest was thus able to drastically increase test coverage without incurring additional costs for external equipment. With this concept, even the smallest PCBs with limited test access can be easily tested – even if they are densely populated with tiny components.

As a leading partner in the electronics industry, Digitaltest develops and produces automated test equipment (ATE) for electronic circuit boards, software for automating production, and quality management systems. Digitaltest is known for innovative solutions for optimizing the entire manufacturing process – as an interface between CAD, the testing process and production itself. We also offer comprehensive service and support, including complete outsourcing of PCB testing at locations worldwide.

40 years of cutting-edge technology, reliability, and value retention in automated test systems.

www.digitaltest.com

Digitaltest GmbH

Lorenzstr. 3

76297 Stutensee

Telefon: +49 (7244) 9640-0

Telefax: +49 (7244) 9640-90

http://www.digitaltest.com

Managing Director

Telefon: +49 (7244) 96 40 -24

E-Mail: sarah.boctor-vauvert@digitaltest.de

Marketing

Telefon: 0722496400

E-Mail: dennis.margulies@digitaltest.com

![]()