Spreitzer ALUMESS fixturing systems allow clamping solutions within minutes. They are designed for flexible use at the measuring station, on coordinate measuring machines, on optical measuring devices and in computer tomographs (CT). They are characterized by easy use, handling and universal applicability. With very limited expenditure, maximum flexibility can be achieved; the systems can always be easily adapted to new measuring tasks. The goal is to enable rapid changeover of the fixtures with constantly changing measurement tasks. Especially newcomers in coordinate measuring, as well as users in the subcontracting measurement benefit from the quick and easy-to-use systems.

Since 1993, Spreitzer has consistently relied on palletizing on the measuring machine. The focus is on fast set-up and changeover. Parallel to the ongoing measurement, the user can set up new clamping solutions and promptly convert the machine in just a few simple steps. All fixturing solutions in the different ALUMESS systems can be quickly changed. They improve the measurement process and increase the production volume per shift.

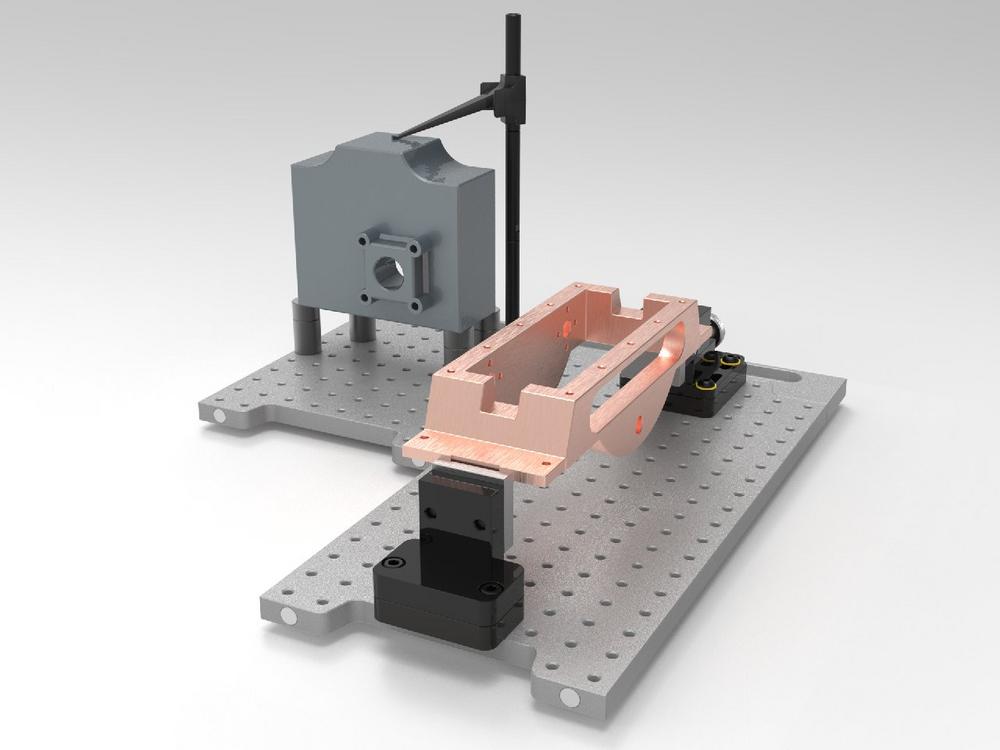

The following two new versions supplement the four already existing systems and now allow the user maximum flexibility:

1. ALUMESS.easyloc accelerates the measuring process with modular, combinable, magnetically interlocking quick-change clamping solutions, which can be used for both tactile and optical measurements. https://vimeo.com/658089341

2. ALUMESS.xray convinces with X-ray transparent clamping technology for industrial computer tomography. Both molded parts and geometrically defined workpieces can be quickly and easily fixed. https://vimeo.com/574411546

These two new systems are compatible with the four previous available systems. Cross-system assemblies and extensions are therefore easily possible. Once a decision has been made in favor of a specific system, this means that there are no restrictions on subsequent, expanded measurement tasks.

The four previous and still valid systems are:

ALUMESS.basic provides the easiest mounting at the measuring station as well as changeover within seconds. All customers’ workpieces can be fixed true-to-contour; the clamping device can be flexibly combined.

ALUMESS.junior can be characterized as very user-friendly and highly flexible when used on the coordinate measuring machine. Other advantages are easy palletizing and low entry prices.

ALUMESS.maxx impresses on the coordinate measuring machine by extreme robustness and maximum universal applicability. The consistency of the hole grid ensures a reproducible assembly.

ALUMESS.optic enables flexible workpiece fixation on optical measuring instruments. The system is ideally suited for direct and transmitted light; changeover within seconds and palletizing is possible.

The main advantages of Spreitzer clamping technology are obvious: The direct order from the manufacturer stands for an optimal price-performance ratio. The round 30 years of experience in development and manufacturing guarantees the highest quality by high degree of specialization of its employees. The Spreitzer development team is focused on the processing of customer requests as fast as possible.

Spreitzer develops individual clamping concepts for the customers according to their photos, drawings and descriptions. Then Spreitzer designs a custom clamping concept and builds an appropriate fixture, sends photos to the customer and a part list of the necessary modular elements. In close contact with the customer, Spreitzer creates specific Starter Sets due to customers´ ideas and budget.

Spreitzer provides immediate advice and fastest help with any problems, special requests and changes or extensions of the clamping devices.

Thus compared with other producers, the Spreitzer clamping technology stands for high grade individualization, sensitive specification, substantial cost reduction and dedicated customer support.

This Southwest Germany based family business Spreitzer GmbH & Co. KG was founded in 1983 with its headquarter in Gosheim (near Tuttlingen). The company is one of the most innovative suppliers of advanced workholding technology as well as concentricity gages. As a turn-key partner of machine tool manufacturers, Spreitzer is well known for its highly efficient solutions in the field of custom made fixtures.

Spreitzer GmbH & Co. KG

Brücklestr. 21

78559 Gosheim

Telefon: +49 (7426) 9475-0

Telefax: +49 (7426) 9475-20

http://www.spreitzer.de

Telefon: +49 (7426) 9475-0

E-Mail: info@spreitzer.de

![]()