The next-generation printing machine provides garment decorators and screen printers with a unique tool for mastering the current and future challenges of the textile supply chain. Notably, the high-volume machine delivers typical annual production capacity up to hundreds of thousands impressions.

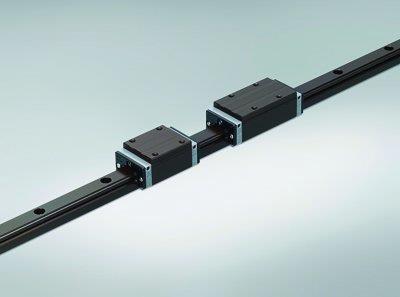

All of the company’s fully integrated printing solutions provide quality, reliability and value to customers, but meeting these objectives means using appropriately specified components. When developing its new printer, the company knew that the linear guides for providing motion in the all axes would have to overcome a specific set of challenges. The inside of a printer is a challenging environment for linear guides because the combination of humidity and evaporation caused by the printing process leads to high wear. With the machine manufacturer insisting on premium brand products and reliable supply partners, the company turned to NSK for the solution. NSK’s team of expert engineers undertook a comprehensive review of the application and working environment, recommending its NH/NS series linear guides, which feature a special surface treatment to protect against the causes of wear.

NH/NS series linear guides offer many notable attributes, including far greater service life due to the inclusion of innovative features like specially developed ball groove geometry. In addition, up to 30% more dynamic load rating (over previous generation products) helps to provide end users with double the fatigue life in a significantly more compact and lightweight format. Low-temperature chrome and fluoride low-temperature chrome treatments are also available to deliver even more endurance, while stainless steel versions are ideal for use in potentially corrosive environments.

Aside from the advantageous technical characteristics of NH/NS series linear guides, the industrial digital printer manufacturer wanted flexibility from its potential supplier due to rapid company growth and the machine’s anticipated fast ramp-up from concept to production. However, NSK was able to provide complete assurance of its ability to support demand from its strategically located workshop and warehouse facilities across Europe.

A video about NH/NS linear guides is available on YouTube at https://youtu.be/_62TERdoodU

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 30,400 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2020, the more than 4,350 employees of NSK Europe Ltd. generated sales of over € 792 million.

www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Telefon: +49 (2102) 4810

http://www.nskeurope.de

Telefon: +49 (2102) 481-2152

E-Mail: albayrak-s@nsk.com

Telefon: +34 (600) 780-385

E-Mail: k.matsuo@mepax.com

![]()