Polyamides (PA) compounds have a lot of industrial applications and are well spread in almost all key industries from automotive and consumer products to electronics and medical/healthcare sectors. Although standard PA compounds (e.g. PA6 and PA66) have found their way into expansive industries still their high level of moisture absorption remains as a main concern.

Basically, moisture absorption results in remarkable degradation of mechanical, thermal, and chemical properties of the PA parts over their service period. High-end fully aromatic polyamides with less moisture absorption are considered as a solution; however, they are costly and sometimes special processing condition need to be conducted.

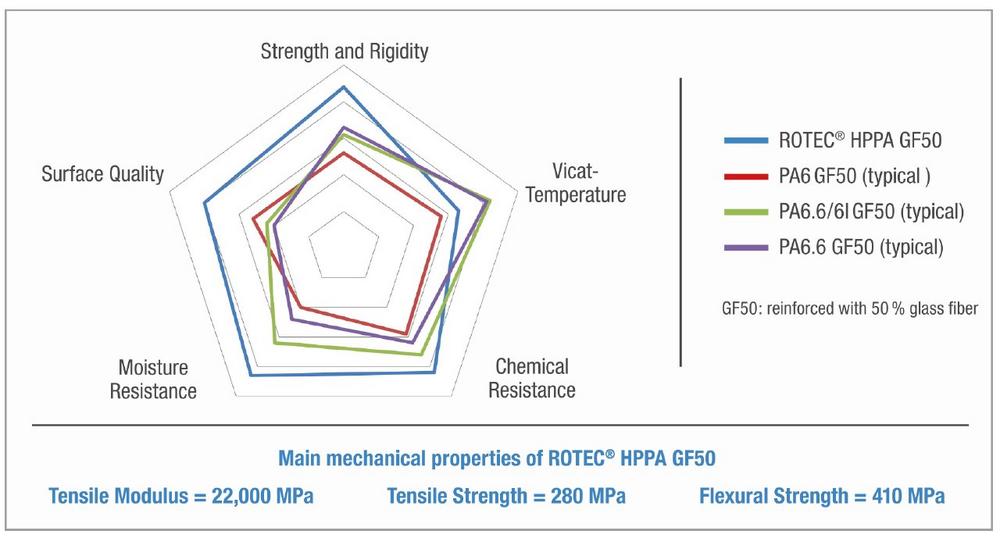

The newly developed ROTEC® HPPA is a high performance polyamide that fills the process and performance gap between standard polyamides and the high-end aromatic polyamides. ROTEC® HPPA contains an aromatic ring in its main chain that provides superior advantages, mainly higher strength and slower rate of moisture absorption. These make ROTEC® HPPA well-suited for variety of applications; especially cost-effective alternative to metals due to its high strength to weight ratio.

The high strength and rigidity of ROTEC® HPPA GF50 makes it possible to reduce weight through decrease of part thickness. In addition, ROTEC® HPPA GF50 (density 1.65 g/cm3 ) possesses very low thermal expansion close to that of aluminum (density 2.70 g/cm3 ) and zinc alloys. The combination of strength and low thermal expansion allows ROTEC® HPPA GF50 to be served as a true metal replacement solution and insert molding with metals applications.

ROTEC® HPPA CHARACTERISTICS:

> A unique combination of metal-like strength and aesthetics

> Very high rigidity and resistance to mechanical stresses

> Excellent flowability; suitable for very thin wall parts or injection of large structural parts

> Low thermal expansion

> Very smooth and high gloss surface even with high glass fiber content; suitable for painting, metallization or producing naturally shiny parts

ROTEC® HPPA ADVANTAGES OVER STANDARD PA6 AND PA66 POLYAMIDES:

> Up to 60 % slower rate of moisture absorption

> Up to 30 % stronger, and higher rigidity

> Better chemical resistance

> Less change in weight/dimension over service period

> Higher surface quality

ROTEC® HPPA APPLICATION AREAS

> Automotive: exterior and interior parts such as mirror housings, door handles, headlamp surrounds, clutch pedals & cylinders

> Aviation: lightweight structural components

> Leisure/sports: lightweight accessories, sport bicycle frame and components, skiing bindings

> Appliances: vacuum cleaner motor supports & levers, shaver heads

> E&E: induction motor supports and safety switches, coil bobbins, stator cores

ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, ROMIRA sets standards for technical plastics with its profound competence and synergetic know-how.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

E-Mail: m.vaezi@romira.de

![]()