- Standard and high torque precision strain wave gear with optimally matched gearbox main bearing for compact, powerful, and cost-effective robot joints

- Integrated torque sensors allow cobots to be used in new and sophisticated areas of application

- The world’s first smart lubricator eliminates time-consuming routine tasks and simplifies the process of supplying lubricant to machines

Schweinfurt/Nuremberg, Germany | November 2, 2022 | At SPS 2022 in Nuremberg, the focus will be on smart and digital automation solutions. And that is exactly what Schaeffler will be presenting: innovative system components for more performance, precision, and cost effectiveness in a wide range of applications for industrial and lightweight robotics. With its intelligent maintenance solutions for predictive maintenance, Schaeffler is responding to current industry requirements for reduced downtimes and greater safety.

Precision strain wave gear for robotics

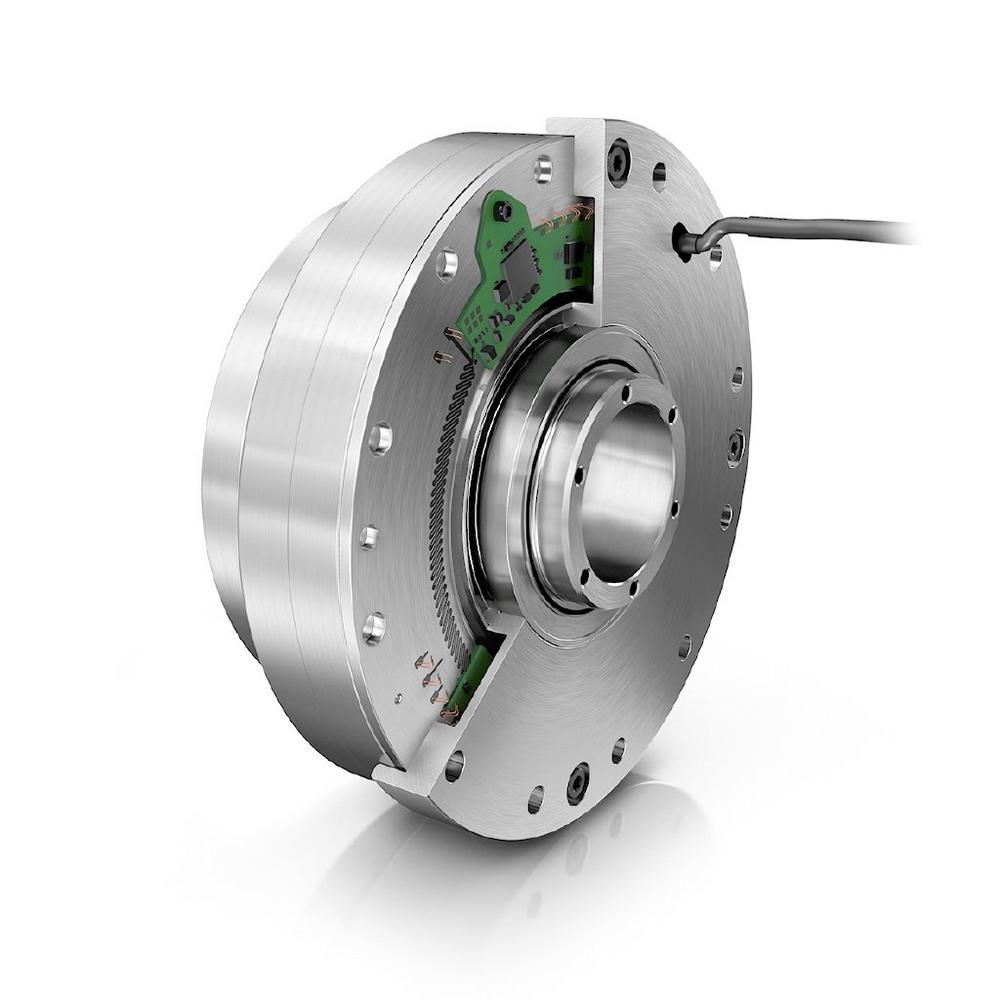

Schaeffler will introduce two series of precision strain wave gears for robotics applications to industry professionals at SPS 2022: RT1 for the high-torque range and RT2 for standard torque applications. The RT2 series offers an extremely wide range of variants and very easy integration into robot design. It covers around 80 percent of standard cobot applications. Thanks to their high torque density, the RT1 precision strain wave gears allow for especially compact articulated arms for higher than average loads. Their backlash-free, wear-resistant toothing guarantees maximum positioning accuracy over the entire service life of the gear. The low weight and compact design make RT1 precision strain wave gears ideal for use in cobots.

The precision strain wave gears from the high torque range are also available with integrated torque sensors (option RT1-T). Compared with many of the solutions available on the market, the sensor technology delivers precise signals without any loss of rigidity in the overall mechanical system. The integrated sensor system supports safety functions and highly accurate positioning and process control, and can be used for active vibration compensation. As a precision strain wave gear that is currently unrivaled, the RT1-T has the potential to tap into a wide range of new application areas in lightweight robotics, where reliably high accuracy is required. Typical applications could include e.g. machine tool construction, industrial production, the food and beverage sector, or medical technology.

Optime C1 smart lubricator

Optime C1, the world’s first smart lubricator launched on the market by Schaeffler last year at a virtual event, delivers an extremely simple yet safe and efficient maintenance process, especially in the case of sensitive or complex applications. As a component of the integrated IoT solution OPTIME Ecosystem, it enables the lubricant management of an entire production line to be fully automated, which in turn simplifies the maintenance process. The smart monitoring and automated processing, combined with intuitive web- and app-based operation, ensure the safe and economical use of lubricant. At the same time, Optime C1 prevents premature failures due to incorrect lubrication and thus improves the availability and service life of the production equipment to be monitored such as drives, bearings or gearboxes.

The SPS show will take place in Nuremberg from 8-10 November. Schaeffler will be showcasing its products and services at Booth 262 in Hall 3. For free tickets and more information, go to: SPS – Smart Production Solutions | Schaeffler medias.

Schaeffler Group – We pioneer motion

As a leading global supplier to the automotive and industrial sectors, the Schaeffler Group has been driving forward groundbreaking inventions and developments in the fields of motion and mobility for over 75 years. With innovative technologies, products, and services in the fields of electric mobility, CO₂-efficient drives, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion and mobility more efficient, intelligent, and sustainable. The technology company produces precision components and systems for drive train and chassis applications as well as rolling and plain bearing solutions for a multitude of industrial applications. The Schaeffler Group generated sales of approximately EUR 13.9 billion in 2021. With around 83,000 employees, the Schaeffler Group is one of the world’s largest family companies. With more than 1,800 patent applications in 2021, Schaeffler is Germany’s third most innovative company according to the DPMA (German Patent and Trademark Office).

Schaeffler Technologies AG & Co. KG

Industriestraße 1-3

91074 Herzogenaurach

Telefon: +49 (6841) 7010

Telefax: +49 (9132) 8249-50

http://www.schaeffler.com

Leiter Kommunikation Industrial

Telefon: +49 (9721) 91-3934

E-Mail: bulutysu@schaeffler.com

Kommunikation Schaeffler Industrie

Telefon: +49 (9721) 91-3873

Fax: +49 (9721) 91-3375

E-Mail: johanna.katzenberger@schaeffler.com

![]()