As part of continued commitment to providing exceptional quality service to customers, Quickparts UK develops solutions designed for complex and technically challenging metal 3D printing, creating a strong competitive position in the aerospace market.

“The announcement reflects our dedication to strengthening our presence within the European market to deliver high-quality products to our growing portfolio of aerospace companies.

“Aside from an exceptional manufacturing facility, behind our successful product is a cross-engineering team aligned to support and advise customers with suitable solutions for the required application in terms of manufacturability, material selection, and post-processing, comments Daniel Kirk, DMP Manager, Quickparts UK.

The facility has capacity across six metal printing platforms, including a vacuum chamber equipped with DMP 350 machines and a range of specialty materials, together with Maraging Steel 18Ni300, Stainless Steel 316L, Inconel 625, and Inconel 718. The content of capability and capacity allows the facility to support customer programs for prototyping, pre-production, and full series production in various sectors, aerospace, motorsports, energy, and automotive.

Aerospace quality standards

Achieved in 2021, the EN9100:2018 third-party certification of the metallic AM (additive manufacturing) process further enhances the facility’s capability to directly support the supply of parts into the aerospace and equivalent sectors where repeatability, reliability, and safety are considered highly critical.

“The EN9100:2018 certification is a key milestone that exemplifies our ambitious growth plans in Europe’s aerospace industry. We look forward to furthering our success with our extensive technical facility and recognised EN9100 materials,” added Daniel Kirk.

The decision to develop the Quality Management System to align with the requirements of EN9100:2018 has allowed Quickparts to support existing customer programs. This has further enhanced the services provided within the UK facility and ensured AM metal production is in line with the increasing demands for repeatability, reliability, and safety for parts used in performance-critical applications. According to Quickparts UK, during the development of the Quality Management System to EN9100:2018, it was decided to select a range of existing production parts to validate the series-production process.

The production examples selected represented both medium-volume, production-part manufacture, and parts used in performance-critical applications, where safety is also a significant consideration. The overall benefit to the end customer is higher assurance and confidence, which directly supports product conformance for greater performance and safety-critical applications. Therefore, this globally recognised quality management standard for the aerospace sector ensures that Quickparts UK promotes continual quality and safety improvement to reduce errors, leading to cost savings and competitive advantages.

Material summary

The UK facility offers the following materials for Direct Metal Printing (DMP) under EN9100:

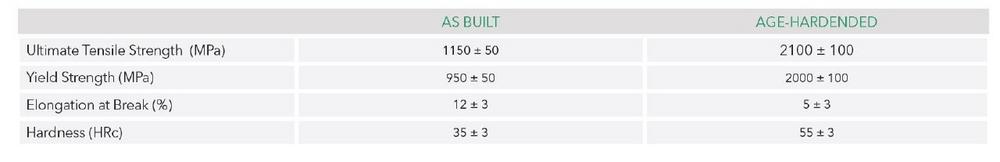

- Maraging Steel 18Ni300 / 1.2709: This versatile steel with excellent mechanical properties can be increased further with a simple age-hardening process. The steel exhibits low residual stress levels and is the first choice for printing, particularly challenging geometry. It is easy to machine, weld, polish, and plate.

- Stainless Steel 316L / 1.4404: This highly corrosion-resistant, austenitic, stainless steel with low magnetic permeability is suitable for a wide range of applications, including medical, food processing, and marine.

- Inconel 625 / 2.4856: This heat- and corrosion-resistant nickel alloy features good tensile and fatigue properties. It also promotes resistance to elevated temperatures. This nickel alloy demonstrates remarkable protection against corrosion and oxidation. This material is typically used by motorsports, aerospace, and oil and gas industries.

- Inconel 718 / 2.4668: This is another example of heat- and corrosion-resistant nickel alloy with good tensile strength but with fatigue properties at temperatures of up to 650 °C. The nickel alloy’s mechanical properties can be increased with age-hardening (AMS 5662 / 5664). This product is In addition, Quickparts UK also offers other materials, for instance Titanium Ti6Al4V and Aluminium AlSi10Mg, through outsourcing.

About Quickparts UK Limited

Quickparts UK creates custom prototypes, 3D printing, and on-demand parts manufacturing with your additive and traditional manufactured parts made to order and delivered where and when you need them.

Professional-grade additive and traditional manufacturing services by Quickparts, empower designers and engineers with the tools to design, iterate, and produce quality parts directly from digital 3D files.

Reduce production times, speed up iterations, and shorten product development lifecycles with high-quality 3D printed and machined parts from one of our many leading global design and production centers.

Quickparts presents complete on demand manufacturing services, from 3D printed metal and plastic parts to traditional CNC, injection moulding, and cast urethane models. They provide quality produced parts and prototypes with some of the fastest and most reliable turnaround times in the industry. Its large, efficient digital production facilities are able to meet the unique business needs of today’s most advanced manufacturing companies.

Quickparts offers complete on-demand manufacturing services, from 3D printing to traditional manufacturing processes. We empower customers with the tools to reduce production times, speed up design iterations, and shorten product-development lifecycles with high-quality, 3D-printed and machined parts from one of our seven global design and production centres. Our UK facilities are ISO 9001:2015 certified, with expert teams that have been producing parts for more than 20 years.

QuickParts Germany GmbH

Edmund-Lang-Str. 16

64832 Babenhausen

Telefon: +49 (6073) 6896000

http://www.quickparts.com

Quickparts

Telefon: +1 (214) 288-1372

E-Mail: rebecca.larson@quickparts.com

VP, Global Marketing

E-Mail: mitch.underwood@quickparts.com

![]()