Creation of a crucial software interface

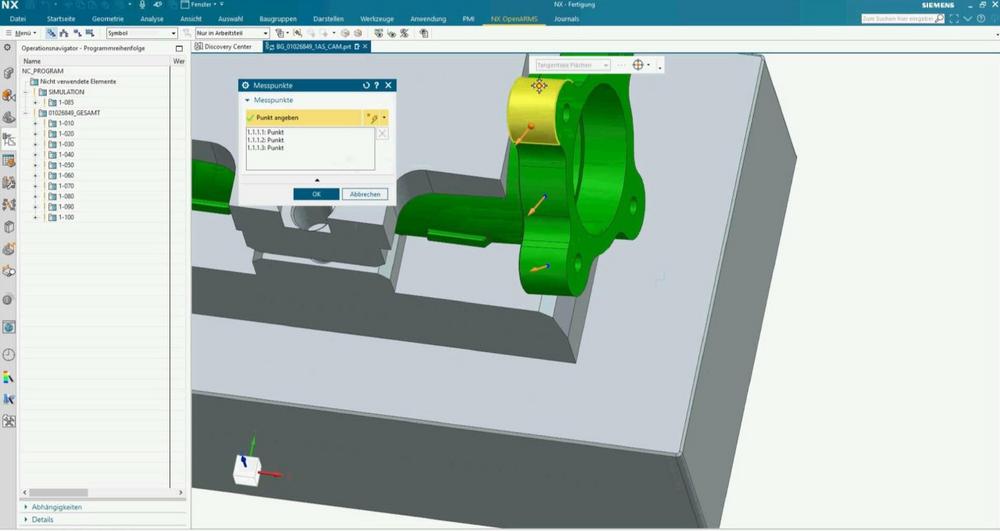

Toolcraft can use the OpenARMS software as a machine-oriented solution to precisely adapt tool paths during the further machining of additively manufactured components. Until now, however, there was no interface to Siemens NX, which made the transition from engineering to manufacturing much more difficult. In close coordination and cooperation between JANUS, BCT and toolcraft, this interface was designed and ultimately programmed and implemented by JANUS Engineering AG. Measuring points can now be selected directly on the CAD model in the Siemens NX environment and the measuring operation can be transferred to OpenARMS via the interface with just one click. The automated adaptive post-processing can then take place on the component by OpenARMS. This has enabled toolcraft to significantly advance the automation of the manufacturing process chain for additive components.

In the future, the medium-sized company will continue to cooperate with BCT and JANUS Engineering to explore and unlock other areas of potential offered by interface programming. For instance, plans are in place to develop a training course on this topic at AMbitious – a business area of toolcraft specialising in training, consulting and software in the area of additive manufacturing. This will be a "one-stop training" with Siemens NX and OpenARMS and their use.

The medium-sized family-owned company, located in Georgensgmünd and Spalt, was founded by Bernd Krebs in 1989. toolcraft is a pioneer of forward-looking technologies, such as additive manufacturing and the construction of customised turn-key robotic solutions. As a provider of comprehensive solutions, toolcraft covers the entire process chain, from the initial idea to manufacturing, quality assurance and testing in the areas of CNC machining, additive manufacturing, injection moulding and mould making. Its clients include market leaders in the semiconductors, aerospace, medical technology, optical, special machinery manufacturing, motor sports and automotive industries. Building close working relationships with collaborative partners as well as universities, other institutions of higher education and research centres is an important part of its corporate philosophy.

toolcraft AG

Handelsstraße 1

91166 Georgensgmünd

Telefon: +49 (9172) 6956-0

Telefax: +49 (9172) 6956-560

http://www.toolcraft.de

Marketing

Telefon: +49 (9172) 6956171

E-Mail: juliarodenbuecher@toolcraft.de

![]()