Today’s coupling systems have to be light, extremely stiff and self-locking. In addition, they must be able to be monitored electrically and operated as intuitively as possible. In doing so, they can avoid the disadvantages of electromechanical or hydraulic clamping systems. Hydraulic systems require extra supply lines and pump systems and are maintenance-intensive.

Electromechanical versions, on the other hand, have other disadvantages. They add significantly to the overall weight of the couplers and can be a problem during power outages. Due to the high gear ratio, loosening the clutch parts can be difficult.

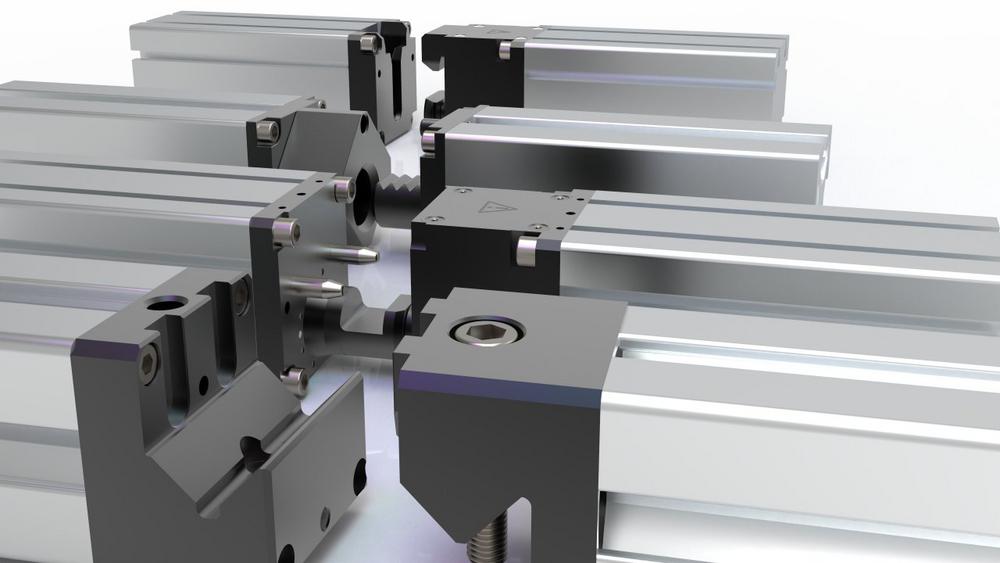

JAKOB Antriebstechnik offers profile rail couplings that can be easily used in connection with all standard profile rails. They are attached either directly or using adapter plates to existing profile rails from various manufacturers and are therefore also ideal for

retrofits. The separation to the interchangeable busbar can take place both in the vertical (PKV series) and horizontal (PKH series) direction. The patented, power-boosting wedge clamping mechanism easily closes a joint gap of up to 5mm between the active and passive parts. This clamping kinematics ensures high rigidity and precision of the connection. The generation of the clamping force is guaranteed by an electrical clamping status query and a minimum clamping force in the event of a pressure drop.

The types PKH and PKV can be adapted to all common gripper rail profiles. In addition to the pneumatic-automatic variant, there is also a manual-mechanical version of the clutch systems in the portfolio. These are conventionally fixed with a screw. For the manual application of clamping force, they have a double-thread drive, which actuates the clamping piston. The clutches automatically close even five millimeter wide gaps between the active and passive parts and are electrically queried. It is installed in the gripper rails either directly or using simple adapter plates. In addition, energy couplings can be attached to the automatic systems. ‚With the closing process, these create the electrical and pneumatic connection to the interchangeable rail.‘ The advantages are obvious: The pneumatic solution TYPE PKH-P or PKV-P is light and, like hydraulic systems, independent of power failures, but requires little maintenance and is economical like couplings with an electric drive. In use, the gripper couplings ensure significantly shorter set-up times – and thus increase the productivity of the entire system.

PKV – design features:

The coupling consists of a passive and an active part made of tempered steel. The clamping force is generated in the active part by an axially displaceable locking bolt and a mechanical clamping gear. This structure enables high clamping forces and high dynamic rigidity to be achieved with a low mass. A vertical lifting stroke “K” (see data sheet) is required for changing the tool.

The PKV series is designed for vertical coupling operations, available both as a fully automatic pneumatically operated version PKV-P and as a series PKV-M with simple manual operation.

PKH – design features:

The PKH series corresponds to the PKV series, but is designed for horizontal clamping processes. It is also available in a pneumatic version (PKH-P) and a manual version (PKH-M).

PKP – design features:

The PKP series is a vertical linear coupler with manual operation. The clamping process is achieved by tightening a screw. The production from aluminum makes the series more cost-effective.

PVH M

The profile rail coupling PVH-M is designed for horizontal coupling with high precision and rigidity. It is tensioned and released manually.

JAKOB Antriebstechnik GmbH

Daimlerring 42

63839 Kleinwallstadt

Telefon: +49 (6022) 22080

Telefax: +49 (6022) 220822

https://jakobantriebstechnik.de/

Marketing

Telefon: +49 (6022) 220855

Fax: +49 (6022) 220822

E-Mail: moeller@jakobantriebstechnik.de

![]()