Continual investment in efficient and modern plants ensures the ability to adapt to new requirements and product innovations. ROWA Masterbatch has successfully completed the renovation of an additional production plant at its Pinneberg site. The approx. 700 m² area was stripped out and refurbished to create the technical conditions for the capacity expansion according to the most modern standards. Special attention was given to the optimum energy efficiency of the supply and exhaust air system with heat recovery.

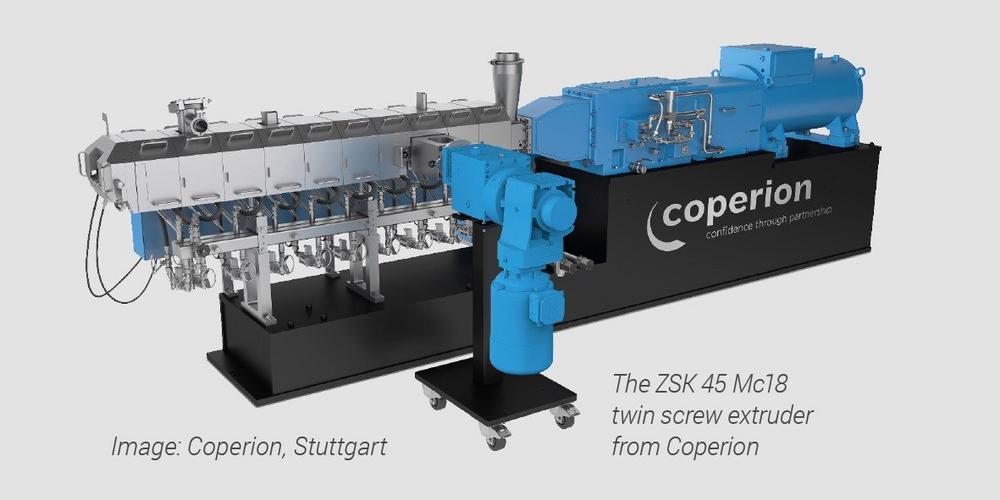

The first of three planned production plants has recently successfully entered into operation: This plant, which is centered around a ZSK 45 Mc18 twin screw extruder from Coperion, enables reliable production of masterbatch to a consistently high quality standard. The plant is designed to allow ROWA Masterbatch to react flexibly to all market requirements. Several container mixing systems are installed upstream of the extruder. The ingredients are fed into the ZSK twin-screw extruder through gravimetric feeders, where they are very carefully dispersed and homogenized in an extremely short time. Particularly shear-sensitive functional additives and pigments can be added and processed downstream via a ZS-B side feeder. Depending on the requirements, the masterbatch flow can be both strand pelletized and underwater pelletized after exiting the ZSK extruder. Coperion has congratulated ROWA Masterbatch on this forward-looking production expansion and is very proud to be part of the project with the ZSK 45Mc18.

The ROWA GmbH was established in 1958 and is a partner in the ROWA GROUP of companies. The brand ROWA stands for technical competence, modern product design and customer oriented service the world over. Tailored customer solutions are part of the ROWA tradition and are a matter of course! The development of new products, the search for alternative raw materials and the constant and sustained optimization of our processes, coupled with modern technology, motivated employees and economical environment protection enjoy the highest priority in our company. In 2010 the ROWA GmbH has been renamed into the ROWA GROUP Holding GmbH and the departments Lack and Masterbatch were newly formed as ROWA Lack GmbH and ROWA Masterbatch GmbH specialist division: Color and additive masterbatches.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

ROWA Masterbatch

E-Mail: info@rowa-masterbatch.de

![]()