In the latest versions of the "Cylindrical gear pair" and "Planetary gear stage" calculation modules, the old DIN 3961 from 1953 for gear tolerances and tooth space allowances, which has been withdrawn for many years, has been integrated in response to numerous user requests. This makes it much easier for users to recalculate cylindrical gears on the basis of old drawings and is particularly helpful when manufacturing spare parts or updating drawings. In addition to DIN 3961:1953, the tolerance standards DIN 3961, DIN 58405, ISO 1328 and ANSI/AGMA 2015 are available for the calculation of cylindrical gears. Furthermore, the number of decimal places for the input fields can now also be individually configured in the "Cylindrical gear pair" and "Planetary gear stage" modules. For the design dimensioning available in both modules, further options for variant calculation have been implemented, such as "Allow specific sliding > 3" or "Allow small geometry errors".

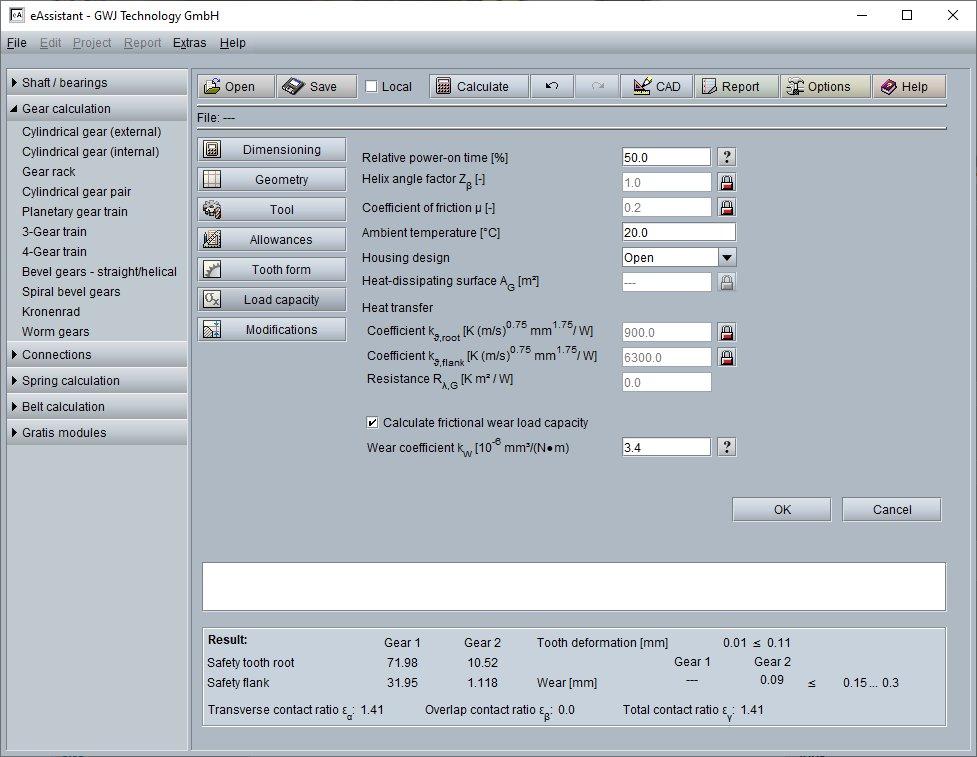

Furthermore, the eAssistant module "Cylindrical gear pair" now allows the calculation of the wear load capacity according to VDI 2736 for dry-running plastic/plastic or plastic/metal pairings. In the load capacity calculation according to DIN 3990, method B or ISO 6336, method B, the individual specification of further factors, such as roughness, lubricant, speed or size factor, is now possible.

With the ISO/TR 6336-30 published in December 2022, 8 practical examples for the current ISO 6336:2019 are now available. GWJ uses these examples to verify its calculation modules, which include ISO 6336 or DIN 3990. The comparative calculations carried out in the meantime matched very well with the practical examples of ISO/TR 6336-30. For all 8 examples, the absolute deviation in the calculated safeties is ≤ 0.01. These results again reflect the high quality of the eAssistant calculation modules.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date.

Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

![]()