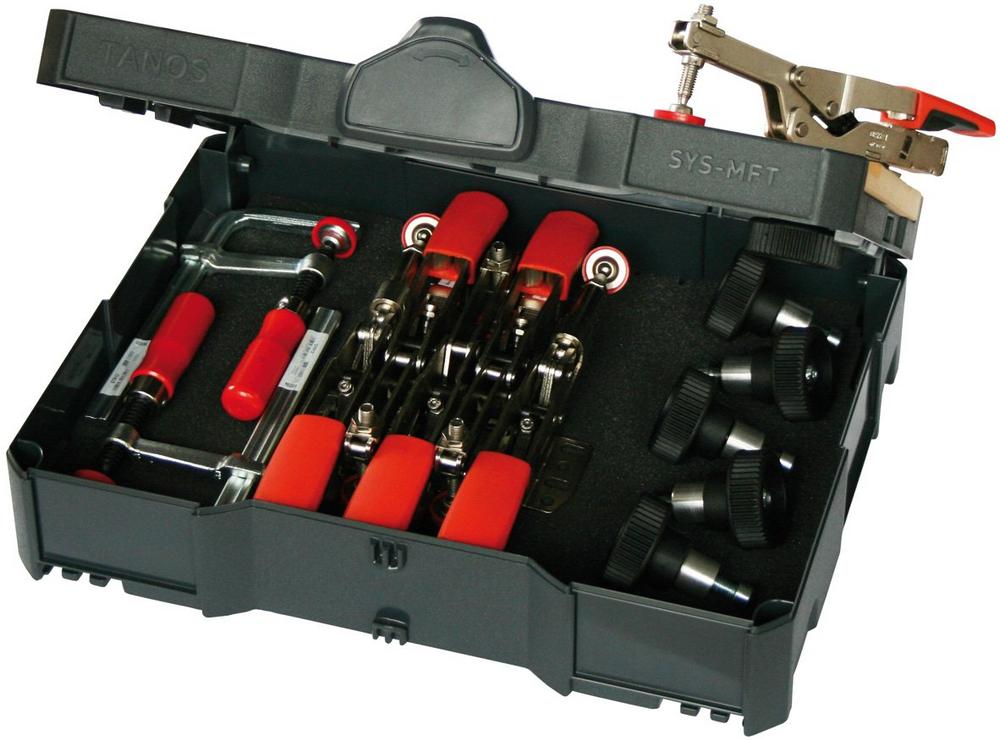

The new BESSEY toggle clamp systainer STC-S-MFT from BESSEY makes everyday work much easier for craftsmen who often find different conditions in a variety of locations.

The systainer has a wood insert with a 20 mm drilled hole integrated into the lid. This allows the stackable storage and transport case to be also used as a small mobile work table. The contents of the systainer – four STC-HH50 horizontal toggle clamps, two STC-IHH25 push/pull clamps, six STC-SET-T20 accessory sets for multifunction table and two GTR12 all-steel table clamps – mean the craftsman has three practical options for fixing a workpiece. The table clamps can be inserted directly into the hole in the lid whereas the two toggle clamp models are each used in conjunction with the adapter.

All clamping devices of the toggle clamp systainer STC-S-MFT can also be used on multifunction tables with a 20 mm hole diameter and counter thickness of at least 19 mm up to a maximum of 25 mm. Festool MFT as well as Sortimo WorkMo fulfil these requirements.

Thanks to the ingenious tool/systainer combination STC-S-MFT, every craftsman can benefit from the numerous advantages of the variable toggle clamps at any time and anywhere. For example, this set includes the ability to clamp different workpiece thicknesses without adjusting the clamping screw manually and with practically the same clamping force – up to five times faster than with conventional clamps. This time saving is made possible by the infinitely variable clamping width of up to 35 mm for horizontal clamps and up to 13 mm for push/pull clamps. But that’s not all. The clamping force of BESSEY toggle clamps can also be individually adjusted to a maximum force of up to 2,500 N by means of an adjusting screw in the joint to suit the workpiece at hand. When the clamp is used in conjunction with a flexible pressure plate with a removable protective cap, fragile materials such as veneered or varnished surfaces can be clamped in a gentle manner.

At BESSEY, we have a long tradition of producing such innovative, practical product solutions as this. Since the cold drawn steel plant was founded in Stuttgart in 1889, the Bietigheim-Bissingen based company continues to raise the bar in clamping and cutting technology. Currently offering more than 1,600 products, BESSEY has a specific solution for practically every application. Our focus is on precision and durability, convenience and safety.

"To stop improving is to stop being good." This was the motto of company founder Max Bessey and it remains our guiding principle today -in all that we do and produce. This means that we are constantly developing new products and improving existing ones to make the user’s life easier, on the basis of innovative ideas. Such innovations are worthwhile.

BESSEY Tool GmbH & Co. KG

Mühlwiesenstraße 40

74301 Bietigheim-Bissingen

Telefon: +49 (7142) 401-0

Telefax: +49 (7142) 401-333

http://www.bessey.de

Marketingreferentin

Telefon: +49 (7142) 401-279

Fax: +49 (7142) 401-338

E-Mail: walter@bessey.de