Infrastructure adapts to new demands in order to ensure that it remains compatible for the coming IIoT and that the demand for ever more intelligent sensors can be met. Devices are getting smaller and smarter, and the connector that’s needed is developing in step with this trend. HARTING kicked off the process of standardising new interface standards with the new hero of Industrial Ethernet communication ("Captain ix") back in 2016. Today, the HARTING ix Industrial® is a market-available connector that enables device manufacturers to design their devices up to 40% smaller.

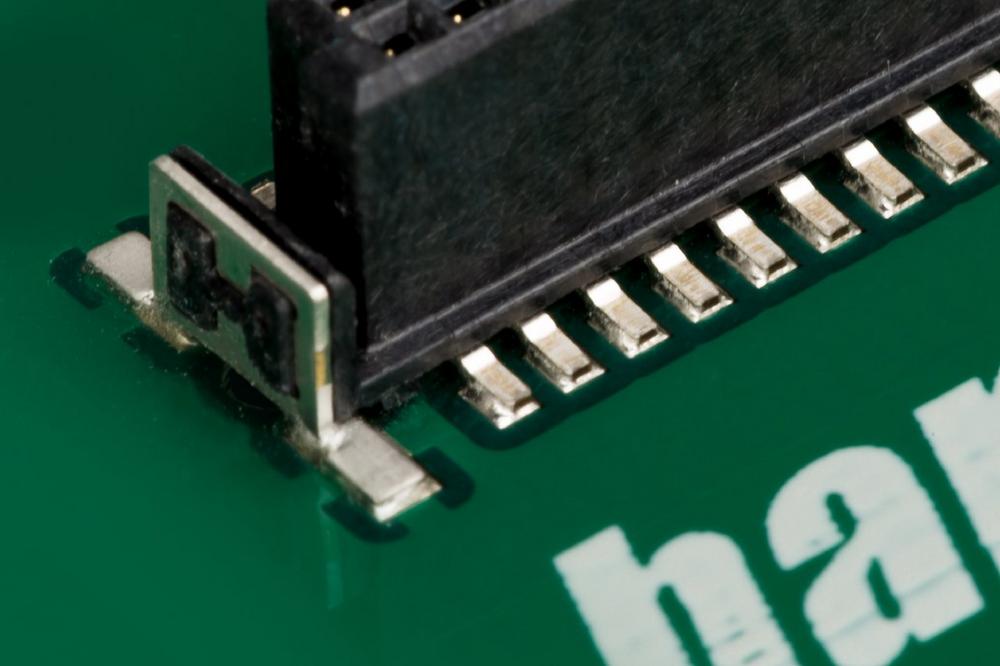

In order to manufacture devices efficiently, connectivity must support an optimal manufacturing process. SMT/SMD assembly technology for all interfaces is required to achieve efficient production. In order to further support automated production, printed circuit board sockets are available on rolls in which device sockets are accommodated in pick & place-compatible manner. Subsequent handling of the interfaces on the devices is also geared towards performance. Cutting assembly time while simultaneously simplifying and improving operation is one of the indispensable cornerstones of a modern interface.

The PushPull locking technique represents a very significant aspect here, since previously employed interlocks such as screw technology will no longer be adequate for ever shrinking connections. As a result, the handling aspect of connectivity is assuming increasing importance. HARTING PushPull technology increases operating safety and efficiency during use.

In order to also make the power supply component of devices simultaneously smaller yet more powerful, HARTING will enhance its M12 Power series in spring 2019 by adding the standardised K coding for power supply. Offering 7.5 kW at 630 volts and 16 amps, the device interface provides enough power for compact yet powerful drives and represents a future space-saving alternative to 7/8-inch solutions, while also keeping in step with the miniaturisation trend.

The HARTING Technology Group is one of the world’s leading providers of industrial connection technology for the three lifelines of Data, Signal and Power and has 13 production plants and branches in 44 countries. Moreover, the company also produces retail checkout systems, electromagnetic actuators for automotive and industrial series use, charging equipment for electric vehicles, as well as hardware and software for customers and applications in automation technology, mechanical and plant engineering, robotics and transportation engineering. In the 2016/17 business year, some 4,600 employees generated sales of EUR 672 million.

HARTING Stiftung & Co. KG

Marienwerderstr. 3

32339 Espelkamp

Telefon: +49 (5772) 47-0

Telefax: +49 (5772) 47-400

http://www.HARTING.com

Referent Presse- und Öffentlichkeitsarbeit

Telefon: +49 (5772) 47-1744

Fax: +49 (5772) 47-400

E-Mail: michael.klose@harting.com

Zentralbereichsleiter Publizistik und Kommunikation

Telefon: +49 (5772) 47-244

Fax: +49 (5772) 47-400

E-Mail: Detlef.Sieverdingbeck@HARTING.com