As one of the world’s leading providers of laser-based technologies, Coherent will once again be exhibiting at Formnext (November 19 – 22, Frankfurt, Germany). Formnext is special to the company, as it was the event that was used to launch the first direct additive manufacturing (AM) system – the Coherent CREATOR – back in 2016 to great acclaim. Since then, the installed base of CREATOR systems has grown year on year.

In 2019, Coherent will once more use Formnext as the place to unveil its latest industrial metal AM system to the world. Full details will be revealed at the company’s dedicated press conference, taking place at 10:45 am, Tuesday, November 19, on the show floor (Hall 12.0, Booth C101).

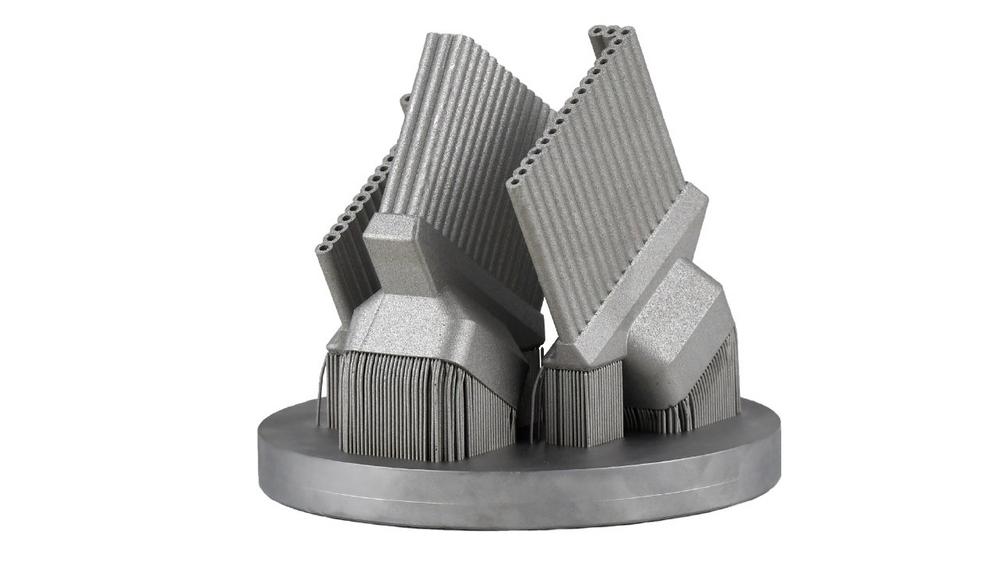

The new AM platform will be on show at Formnext alongside the full range of Coherent additive platforms, including the CREATOR, the CREATOR Hybrid, the EVO CUBE, and the ROBOLASER. As the portfolio of AM systems from Coherent clearly demonstrates, the company is one of a few companies globally that focuses on developing both laser powder bed fusion (L-PBF) and Direct Metal Deposition (DMD) solutions. Both of these processes, which are fully vertically integrated within Coherent, are seeing strong growth across industrial sectors for a range of applications. At Formnext, the DMD highlights on Coherent’s booth will be the EVO CUBE and the ROBOLASER. Both of these systems offer versatile manufacturing options. The ROBOLASER incorporates four process technologies into a single platform for welding, cutting, hardening, and DMD. The EVO CUBE platform is also a flexible tool for metal DMD and welding applications offering cost-effective, high quality laser processing of small and medium sized components.

Beyond the hardware offerings, Coherent will also be showcasing its end-to-end solutions for additive manufacturing at Formnext, as well as dedicated application solutions. Coherent is acutely aware that the AM machine is only one, albeit fundamental, part of the process chain. The pre- and post-processing stages are also vitally important. To this end, the company will highlight a manufacturing process chain laboratory that incorporates a coherent strategy from digital design using the CAM solution APP SUITE through to the finished part.

Coherent believes that the interdependence of hardware and software to achieve maximum productivity and streamline workflows in production environments is the key to unlocking the real potential of AM. It is in this area that the company is dedicating tremendous effort, specifically for the dental industry, which has proved to be a particularly smart fit for AM, and especially the CREATOR. The company’s DENTAL COCKPIT powered by APP SUITE end-to-end production solution for dental laboratory applications will be a highlight on the Coherent Formnext stand. The DENTAL COCKPIT is a dedicated software platform for users of the CREATOR metal 3D printers for dental applications and offers a simplified process workflow and considerable time saving efficiencies.

Ludovico Camarda, General Manager Coherent | OR Laser, commented on the company’s presence at Formnext: “Formnext is the must-attend event for any company offering additive manufacturing processes for industry. We are excited to launch a new system at Formnext this year – one that will illustrate to the industry and visitors to the event how serious we are about metal AM – alongside our well-established machines. We are also looking forward to showcasing our application-specific solutions to a global audience.”

Coherent

Dieselstr. 5b

64807 Dieburg

Telefon: +49 (6071) 968-0

Telefax: +49 (6071) 968-499

https://www.coherent.com/de

PR

Telefon: +49 (40) 733634256

E-Mail: katharina.manok@coherent.com

![]()