- perform® HD – particularly good processing behavior for automotive construction

- precidur® HSM HD – maximum forming capacity for safety-relevant components

- Sample products from perform® and precidur® as well as other innovative steels will be presented by thyssenkrupp Steel from 25 to 28 October at the EuroBLECH trade show in Hannover, Hall 17, booth E33

- Presentation by thyssenkrupp Steel on "bluemint® Steel and the transformation of steel production at thyssenkrupp Steel Europe" on 27 October 2022 from 2:00 p.m. to 2:30 p.m. in the EuroBLECH Presentation Area, Hall 26, booth L60

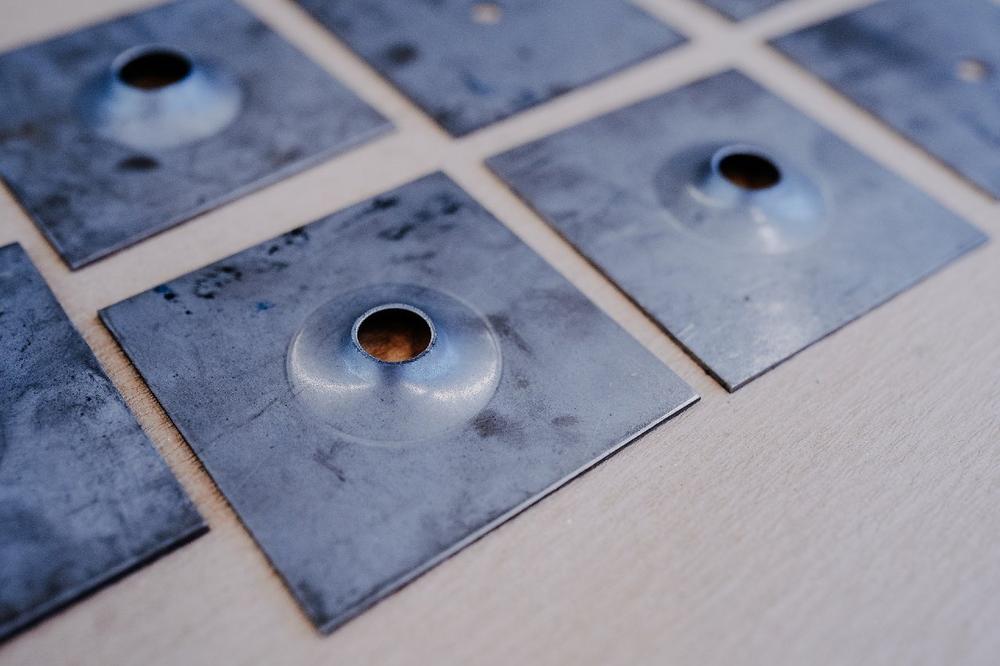

Highly ductile microalloyed fine-grained steels are the first choice when significantly improved formability is required for complex component geometries in the axle or wheel suspension area. thyssenkrupp Steel has developed perform® HD as hot-rolled wide strip and the particularly close-tolerance precidur® HSM HD precision strip for this purpose. The special crystalline structure of the highly ductile microalloyed grades ensures stable mechanical properties. New in the range: microalloyed perform® HD steels in the yield point range from 315 to 550 MPa (hot-rolled wide strip) and the two newly developed grades precidur® HSM 380 HD and precidur® HSM 420 HD (precision strip). Chassis steel CH-W® 660Y760T is now also available hot-dip galvanized. The latter is the lightweight solution for single-skin control arms and comparable demanding components.

perform® HD steels for optimum component-related material selection

Due to their good processing behavior, hot-rolled microalloyed steels have proven their worth in automotive construction – especially in the areas of chassis and seats. The new high-ductility (HD) grades from thyssenkrupp Steel offer convincing features, with a uniform property profile tailored to the intended use at the same time as an increased forming potential. "The new micro-alloyed HD steels are characterized by a significantly narrower range of mechanical properties compared to the standard and have an increased elongation after fracture," says product manager Arne Schreiber. "With the higher-strength grades, the component weight can additionally be reduced. perform® HD steels are ideally suited for seat components such as cushion side members and seat rails or in the axle or wheel suspension area."

precidur® – that little bit extra for complex components

precidur® is used in almost all branches of industry. Particularly in the case of safety-relevant components, functional and design aspects are playing an increasing role alongside reliability – which demands the highest forming capacity of the basic material. Hot-rolled fine-grained steels such as precidur® HSM 380 HD and precidur® HSM 420 HD are particularly suitable for this purpose. They are characterized by symmetrical strip profiles and the rolled mill edge. Compared to proven microalloyed fine-grain structural steels, they make increased forming potential possible with the same strength.

The advantages of microalloyed perform® HD steels at a glance:

· Improved cold formability for complex component geometries

· Guaranteed narrower range of mechanical parameters compared to VDA 239-100 and DIN EN 10149-2 standards

· Significantly increased elongation after fracture

· Lightweight potential through sheet thickness reduction

· Narrowest thickness tolerances for hot-rolled wide strip

· Excellent surface quality

· Reduction of production costs in the stamping shop thanks to application-specific property profile

thyssenkrupp is looking forward to face-to-face encounters and stimulating industry discussions at EuroBLECH 2022. Visit the booth from 25 to 28 October 2022 in Hall 17, booth E33.

thyssenkrupp Steel Europe AG

Kaiser-Wilhelm-Str. 100

47166 Duisburg

Telefon: +49 (203) 52-0

Telefax: +49 (203) 52-25102

http://www.thyssenkrupp-steel-europe.com

External Communications

Telefon: +49 (203) 52-47270

E-Mail: christine.launert@thyssenkrupp.com

![]()